It's been a few years since i last upgraded my 3D printer. During this time a lot of new printer features were invented and several parts got cheap enough for me. Also my printer was havilly used and few parts started to show that thay are worn out. It's time for a bigger maintenance.

Heat bed

Five years ago Průša presented a new heat bed covered by PEI plastic layer. It was a giant leap in printing comfort and quality. Finaly there was no need of covering the bed by ABS juice. Suddenly the print preparation started to be much easier and also white ABS juice residue was finally gone. But it was brand new technology and thus getting such pei foils wasn't easy.

At that time I ordered from China one piece of the PEI film,but it wasn't ideal. It was quite thick (2mm) and I sticked it to a glass pane. That thick glass-pei layer worked as an isolation and I had to heat the bed to a few degrees higher temperature then before. Also the way of mounting was unfortunate. I used paper clips to attach the glass to heatbed which made the printing area smaller. Other problem was removing printed object form the heat bed. I had to remove it using a knife and often demaged it this way.

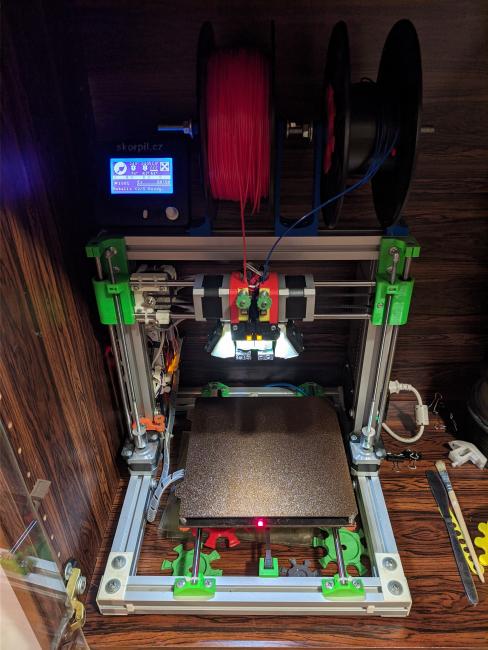

In short I bought a magnetic foil and a thin steel plate covered by PEI. I had to completely disassamble the aluminium heat bed, enlarge mounting holes to make screws flat with the surface and then glue the magnetic foil on it. Steel plate now just sits on the heat bed by magnetic force.

This way I fixed all described problems. No paper clips means bigger printing area. Steel plate can be bent which makes removing printed objects easier and it also coducts heat better.

Printing head

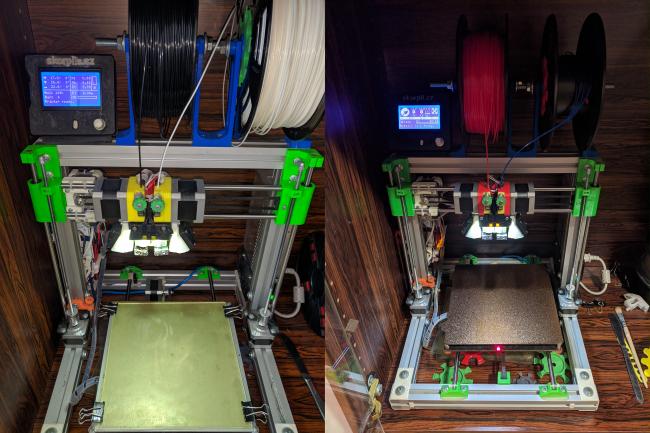

The printing head was a bigger issue. Five years ago I upgraded to a dual extruder head, which can print by 2 colors or 2 materials without manually changing spools during printing. I tweaked the 3D model a bit to be able to mount a led strip to it. My printer sits in a case where there isn't much natural light thus the LED lights are important to me. But the time revealed a big design flaw which my led addon made even worse.

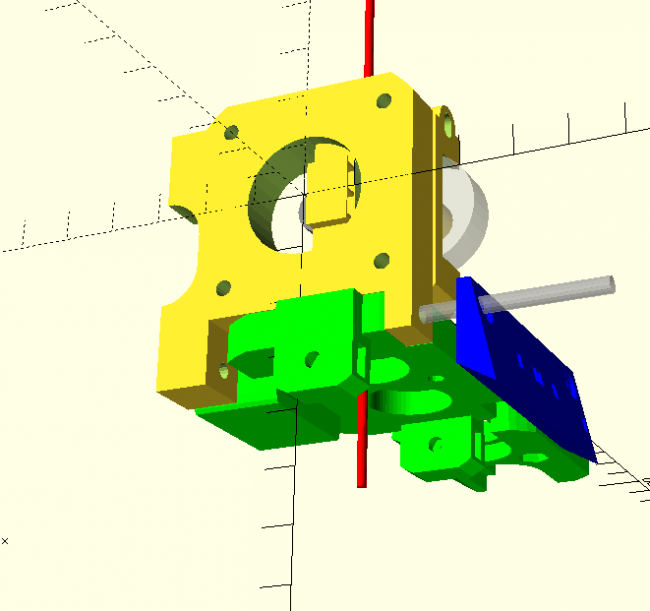

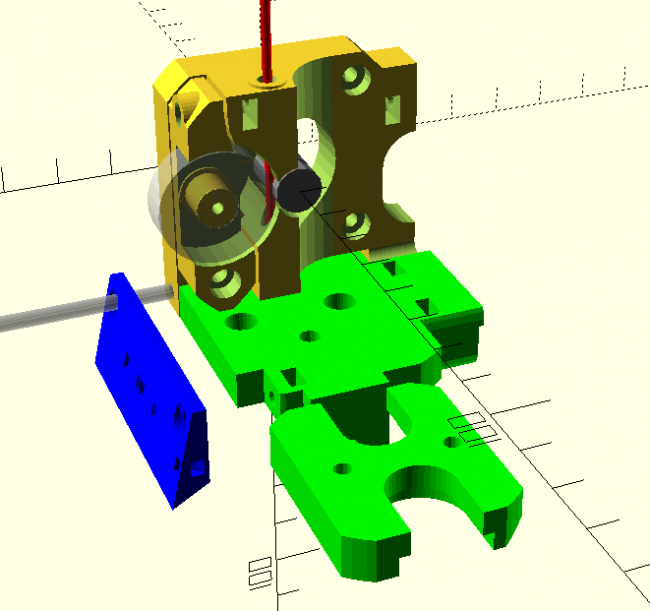

The head is made of three parts independently mountend on a carriage. On top there are left and right extruders, motor assemblies which push plastic wire down to nozzles. On the bottom there is a common nozzle holder. And the former has the design flaw. It is mounted to the carriage horizontally only by two screws and two extruders are generating big additional pushing force from top. Over time this part started to bend and added led mounting holes made this part's rigidity worse.

I consider my solution perfect. I tweaked extruder and nozzle holder parts to interlock to each other by the screws that hold the led strip. Whole printing head becomes a single solid assembly. Pictures below can explain it better. It works.

Firmware

The last upgrade was a firmware. I decided to switch from Repetier to Marlin. The main reason is a bigger community and therefore faster development. For last 5 years repetier didn't release a single new update and I don't thing that there is nothing to fix. Marlin installation and calibration was easy. I used most of the config values from the Repetier one. Man just needs to figure out the name of the variable in documentation to copy the value to.

Because of this switch I can now compare both firmwares. Repetier is definatelly easier to configure for a beginner. They have a web app, where you just fill in all the values and then you download preset firmware package. In Marlin you have to go through C header files and set all the values right there. But variables are commented with explanations of their meaning and there is also good documentation on the web, so no big problem there either. I also liked more the Repetier's graphic display homescreen layout. On the other hand Marlin has official support for Visual Studio Code with a custom extension for it, so config editing is comfortable and mainly firmware flashing is easier there. I also noticed, that Marlin handles nozzle heating better. They have automatic calibration tool, that finds optimal parameters for PID algorithm. Therefore Marlin can maintain very stable teperature. And finally there is the comunity. Marlin has a lot of extensions, manuals and videos that help with any problem.